Industry and Ideas

Turkey Red

Technology Transfers and Changes, Imitation and Global Trade

1 Turkey red is a color named for the place, not the fowl. It is, however, "Turkey" in a very conceptual sense, not bounded by the geographic or political forms of atlas or gazetteer. Turkey red—in French, rouge d'Andrinople or rouge de Turc—was a bright red color on cotton. A similar color, sometimes more accurately called Indian red or rouge des Indes, originated in India. Modern Western viewers would see these shades as "basic," "true," or "common" red, the ancestor of that color found on the ubiquitous red bandanna.

Turkey red is a color named for the place, not the fowl. It is, however, "Turkey" in a very conceptual sense, not bounded by the geographic or political forms of atlas or gazetteer. Turkey red—in French, rouge d'Andrinople or rouge de Turc—was a bright red color on cotton. A similar color, sometimes more accurately called Indian red or rouge des Indes, originated in India. Modern Western viewers would see these shades as "basic," "true," or "common" red, the ancestor of that color found on the ubiquitous red bandanna.

The dyeing of Turkey-red on cotton, though a very late discovery in this kingdom, was established in Glasgow earlier than any part of Great Britain. In the year 1785, Mr. George Mackintosh … engaged Monsieur Papillon, an eminent Turkey-red dyer from Rouen in Normandy, carried him with him to Glasgow, and … built an extensive dye-house near Dalmarnock.

Andrew Brown, History of Glasgow (Glasgow, 1795–97), 2:254.

Although a similar color exists for all media, Turkey red refers almost exclusively to a color for dyed or printed textiles. And, although there are testaments to the constant historic demand for red colors throughout Europe, in the eighteenth century Turkey red was principally an export item, shipped to colonists and traders in the Americas, Africa, and the Middle East.1 The relative lack of interest in the color throughout the German states at this time confirms that role: eighteenth-century German-language descriptions and discussions of Turkey red are almost exclusively republications of articles in popular or general periodicals from other regions of Europe. Except for a few textile districts near the French border, it was not until the nineteenth century that Turkey red and similar colors received the sort of attention it enjoyed in France, Britain, and the Netherlands. reference

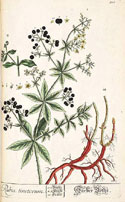

The coloring source for Turkey red may have contributed to the perception of these goods as an item for colonial markets. Its coloring source was madder root which, unlike kermes and cochineal, was cultivated throughout Europe. There were significant differences between traditional European madder reds and this new color, however. The Turkey red process yields a color that is closer to carmine than to dark scarlet or brick reds of European madder-dyeing process. Turkey red is bright and fast and, perhaps most important, it is a technique for cotton rather than wool. reference Merchants and factors in Europe believed the light weight and simple cleaning methods of cotton cloth made it especially attractive to tropical markets.

The coloring source for Turkey red may have contributed to the perception of these goods as an item for colonial markets. Its coloring source was madder root which, unlike kermes and cochineal, was cultivated throughout Europe. There were significant differences between traditional European madder reds and this new color, however. The Turkey red process yields a color that is closer to carmine than to dark scarlet or brick reds of European madder-dyeing process. Turkey red is bright and fast and, perhaps most important, it is a technique for cotton rather than wool. reference Merchants and factors in Europe believed the light weight and simple cleaning methods of cotton cloth made it especially attractive to tropical markets.

There were problems associated with the European imitation of Turkey-red colors, however. The process, as practiced in Turkey, was labor-intensive and expensive. Prepared cotton fibers received successive steepings in lye, olive oil, alum, and dung in addition to several madder baths and aftertreatments. Production could take weeks. Furthermore, the process was not easily adapted to eighteenth-century European printing techniques, and use was limited to unwoven yarns and whole cloths.

5Turkey-red production in Europe is usually considered an achievement of the nineteenth-century cotton-printing industry. Historians of the British textile industry in particular acknowledge an earlier presence but suggest that the impact was insignificant before the founding of certain firms, in Scotland, in the 1780s.2 The Turkey-red industry is presented as a simultaneous effort to import desirable techniques and transfer production—of materials as well as objects—to regions or nations; its technical developments fall securely within a trajectory of increasing industrialization that is a hallmark of the nineteenth century.3 reference If scale of production is a major criterion, then it seems reasonable to ground the growth and development of a cotton-coloring technique in the epoch marked by large-scale factories and an attendant, explosive growth for all aspects of cotton production.

J'ai écrit au Sr Peretié négociant à Smirne mon correspondent les intentions du ministère et après beaucoup de peines et de dangers, il est venu à bout de débaucher deux maitres teinturiers et un compagnon.

Flachat to Trudaine, 20 November 1767, AN F/12/1332.

Even so, we know that European efforts to imitate Turkey red were well underway by the 1740s, and that success made the reputation and fortune of several dyers, chemists, and manufacturers by mid-century. reference Interest in the formulations and processes that create the color was strongest in the districts where cotton manufacture was prevalent—Manchester, Rouen, and, later, Mulhouse. The approach to replication took several forms. Spies were sent to Greece, to Turkey, and later to other European cities to learn the technique. Workers were imported to set up and operate dyehouses specializing in Turkey red. Correspondence with merchants, attachés, missionaries or others stationed in regions where these techniques were a specialty added to the pool of information. reference

Some investigations attempted to reproduce the color without relying on the original process, once it was revealed.4 Finding a means to simplify and so understand Turkey red and its chemistry were a significant part of the attempts to recreate the color. And, throughout this period of European experiment, Turkey-red and Indian-red cottons continued to be exported from the East.5

Dye process for red on cotton

1. Boil cotton in lye of Barilla or wood ash.

2. Wash and dry

3. Steep in a liquor of Barilla ash or soda plus sheep's dung and olive oil

4. Rinse, let stand 12 hours, dry

5. Repeat steps 3& 4 three times.

6. Steep in a fresh liquor of Barilla ash or soda plus sheep's dung, olive oil and white argol.

7. Rinse and dry

8. Repeat steps 6 & 7 three times.

9. Treat with gall nut solution

10. Wash and dry.

11. Repeat steps 9 & 10 once.

12. Treat with a solution of alum, or alum mixed with ashes and Saccharum Saturni (lead acetate).

13. Dry, wash, dry.

14. Madder once or twice with Turkey madder to which a little sheep's blood is added.

15. Wash

16. Boil in a lye made of soda ash or the dung liquor

17. Wash and dry.

Source: John Wilson, An Essay on Light and Colours (Manchester, 1786) 21–22.

Over the decades, trained colormakers, scientific investigators, and others with varying practical or theoretical skills developed techniques to make Turkey red. Patents, publication, and other forms of public acknowledgment for one recipe seemed to encourage announcement of others. The Society of Arts received more than eighteen submissions concerning Turkey red in the years before 1785.6 John Wilson, a dyer in Manchester, twice won a premium from the Society: he received £50 in 1761 for producing the best Turkey red and two years later a second award for making the color brighter.7 reference In France, the first privilège to produce Turkey red was granted about 1747, and the Imprimerie Royale printed instructions in 1765.8 Dozens of others applied for permission to manufacture their Turkey-red process, and French patents were granted in 1783 and 1791.9

Patents, publication, and other forms of public acknowledgment for one recipe seemed to encourage announcement of others. The Society of Arts received more than eighteen submissions concerning Turkey red in the years before 1785.6 John Wilson, a dyer in Manchester, twice won a premium from the Society: he received £50 in 1761 for producing the best Turkey red and two years later a second award for making the color brighter.7 reference In France, the first privilège to produce Turkey red was granted about 1747, and the Imprimerie Royale printed instructions in 1765.8 Dozens of others applied for permission to manufacture their Turkey-red process, and French patents were granted in 1783 and 1791.9

Premierement, c'est avec raison que les auteurs du proces verbal regardent comme nouvelle la couleur dont il s'agit; elle l'est en effet et par se beauté et par sa solidité, car en général les nuances legères des couleurs même les plus belles et les plus solides n'ont ni autant d'eclat a proportion, ni autant de ténacité que les mêmes teintures dans leur plénitude. Ce nouveau rose est par conséquent très estimable, et ne peut manquer d'être très avantageux aux manufactures, parce qu'il doit faire un très bel effet dans les siamoises et autres toiles de coton et fil en coton, soit pour habillements, soit pour meubles.

Pierre-Joseph Macquer, Rapport de roses solides sur le coton, 30 October 1782, AN F/12/994.

Emanuel Osmont, one of the grantees, won an award for adapting his techniques to produce a shade he called rose of Smyrna.10 This discovery excited the interest of Louis-Auguste Dambourney, himself owner of a dyehouse specializing in Turkey red.11 In general, altering the process to make different colors was unusual; there were no "Turkey" blues or browns as there were Prussian greens and reds. Once production methods were known and disseminated, the addition of a final brightening stage that mimicked that of the Turkey-red process began to appear in other dyehouse routines: This was one contribution that the eighteenth-century investigations made to general expections about the textile dyeing process. reference Despite the limitations of Turkey red and related colors—their confinement to textiles, the difficulties of reproduction, the inability to adapt them easily to the more fashionable printed-cotton industry—they are an important model for approaches and solutions to problems of color creation and replication in the eighteenth century. Varied attempts at imitation of a desirable color persisted alongside achievements in understanding of the mechanical and chemical operations of the process. As a difficult project, it remained open to continued interest and investigation.

Notes:

Note 1: André Dubuc, "L'Enigme Rouennaise du Rouge des Indes," in Le textile en Normandie: Études diverse (Rouen, 1995), 167–72; Jacqueline Jacqué, ed. Andrinople, le rouge magnifique: De la teinture à l'impression, une cotonnade à la conquete du monde (Mulhouse, 1995). On wool trade between Britain and the Levant, including the role of dyeing and finishing, see David Mitchell, "Levantine Demand and the London Textile Trades, 1650–1730," Bulletin du CIETA 80 (2003), 49–59. back

Note 2: T. Chateau, L'Historie de la fabrication du rouge turc ou d'Andrinople et la théorie de cette teinture (Paris, 1876); Fernand Miray, Origine et histoire de l'industrie de la teinture en rouge des Indes (dit rouge turc, rouge d'Andrinople ou rouge de Rouen) à Darnétal et à Saint-Léger-du-Bourg-Denis [Rouen, 1932]; A. P. Wadsworth and J. de L. Mann, Cotton Trade and Industrial Lancashire 1600–1780 (Manchester, 1931); Colour Museum Archives: Turkey Red, at http://www.sdc.org.uk/museum/turkeyredarchive.htm (accessed 9 January 2005). back

Note 3: Agustì Nieto-Galan, Colouring Textiles: A History of Natural Dyestuffs in Industrial Europe (Dordrecht, Netherlands, 2001), esp. 19–21 and 50–55. back

Note 4: Guillaume Mazéas, "Recherches sur la Cause Physique de l'Adhérence de la Couleur Rouge aux Toiles Peintes qui Nous Viennent des Côtes de Malabar et de Coromandel," Mémoires de mathématique et de physique présentés à l'Académie royale des Sciences, par divers sçavans, et lûs dans ses assemblées [Savants étrangers] 4 (1763): 1–32; Meeting Minutes for 2 September 1767, Procès-verbaux de l'Académie royale des Sciences 86 (1767); Meeting Minutes for 21 February 1776, Procès-verbaux de l'Académie royale des Sciences 95 (1776); Thomas Henry, "Considerations Relative to the Nature of Wool, Silk and Cotton, as Objects of the Art of Dying; . . . Together with Some Observations on the Theory of Dying in General, and Particularly the Turkey Red," Memoirs of the Literary and Philosophical Society of Manchester 3 (1790): 343–408; [Rapport sur Bonnafant, teinture en coton], 14 March 1782, AdS pochette; Jean-Michel Haussmann, "Observations de M. Haussmann sur Rouge d'Andrinople," Annales de chimie et de physique 12 (March 1792): 196–219; "Addition aux Lettres de M. J. M. Haussmann à C. L. Berthollet," Annales de chimie et de physique 12 (1792): 141–46. back

Note 5: Angélique Kinini, "La Fabrication du Rouge Turc dans la Thessalie de la Fin du XVIIIe Siècle: Les Manufacture de la Ville d'Ampélakia," in Natural Dyestuffs and Industrial Culture in Europe, 1750–1880, eds. Robert Fox and Agustí Nieto-Galan (Canton, Mass., 1999), 71–100. back

Note 6: W. Thompson to the Chemistry Committee regarding red dye with a sample of Turkey red, 14 May 1760, [R]SA PR.GE/110/9/5; Discussion of Turkey Red, November 1760, Committee minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1758–60 [R]S PR.GE/112/12/1; Farmer to the Chemistry Committee regarding Turkey red, 26 March 1761, Committee Minutes of the Chemistry Committee [R]SA Minutes of Various Premium Committees 1760–61 [R]SA PR.GE/112/12/2; Regarding a premium for J. Wilson, 21 May 1761, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1760–61 [R]SA PR.GE/112/12/2; B. A. Lescullier to the Chemistry Committee regarding Turkey red, 16 March 1762, [R]SA PR.GE/110/12/135; Regarding a second premium for J. Wilson, 1763, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1762–63 [R]SA PR.GE/112/12/4; E. Delange of Rotterdam to the Chemistry Committee regarding Turkey red dye on cotton, madder and other subjects, 1763, [R]SA PR.GE/110/14/118; Regarding submission of M. Abrahams, 4 June 1768, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1767–68 [R]SA PR.GE/112/12/9; F. Rheinwald to the Chemistry Committee, 25 October 1768, [R]SA Guard Book PR.GE/110/25/50 and 14 January 1768, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1767–68 [R]SA PR.GE/112/12/9; Letter of Le Grand to Lord Nuncham, read to the Committee, 18 February 1773, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1772–73 [R]SA PR.GE/112/12/14; Letter of Knowck read to the Committee, 18 February 1773 Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1772–73 [R]SA PR.GE/112/12/14; Examination of Mikovini by the Committee, 21 March 1778 Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1777–78 [R]SA PR.GE/112/12/19; Letter of Charles de Schede, 21 December 1784, [R]SA PR.MC/105/10/295; Jacques Schlögel / H. Hazard to Mr. Green of the Society of Arts, 17 February 1784, [R]SA PR.MC/105/10/291; James Briggs to the Chemistry Committee, 9 February 1785, [R]SA PR.MC/105/10/290; Taylor and Cooper to the Chemistry Committee, 3 December 1785, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1785–86 [R]SA PR.GE/112/12/27; Black and Maydwell to the Chemistry Committee, 15 January 1788, [R]SA PR.MC/105/10/181 and Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1787–88 [R]SA PR.GE/112/12/29. See further the RSA Archive Catalogue, at www.rsa.org.uk/archive/archiveSearch.asp. back

Note 7: John Wilson to the Chemistry Committee regarding red dye for cotton, 12 February 1761, [R]SA PR.GE/110/11/12; Regarding a premium for J. Wilson, 21 May 1761, Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1761–62 [R]SA PR.GE/112/12/3; Regarding a second premium for J. Wilson, 1763 Committee Minutes of the Chemistry Committee, [R]SA Minutes of Various Premium Committees 1762–63 [R]SA PR.GE/112/12/4. See also William Bailey, The Advancement of Arts, Manufactures, and commerce; or, Descriptions of the Useful Machines and Models Contained in the Repository of the Society for the Encouragement of Arts, Manufactures, and Commerce. . . . (London, 1772): 1:331. back

Note 8: Notice d'un Arrêt du Conseil donnée une privilege à Daristoy de Rouen pour son secret de teinture rouge d'Andrinople, 26 August 1747 AN F/12/2424.back

Note 9: "Dossier de Alteriac," 20 January 1759, ADSM C/151; "Dossier de Chaubert," (28 January 1791) AN F/12/1329; "Dossier de Goudard," 23 August 1747, AN F/12/94; "Dossier de Myot," 1765, AN F/12/2259; "Dossier de Flachat," 1770, AN F/12/1330; "Dossier de Deschamps et Regimbard," 7 March 1770, ADSM C/151; "Dossier de de Lange (30 May 1766, 10 September 1766, 22 February 1772 AN F/12/1329; "Dossier de Eymard," 1776, AN F/12/2259; "Dossier de Pinal," 1779, AN F/12/2259; "Mémoire sur la teinture par le Page, éleve des manufactures," 17 March, 1779, AN F/12/1330; "Dossier de Gallay, 10 April 1780, AN F/12/2259; "Dossier concernant le secret de rouge des Indes par Pluard, 27 November 1781, AN F/12/1334; "Dossier sur de Lorme," July 1787, AN F/12/1331. back

Note 10: "Notice de un Pension de 600 livres donnée à Osmont maitre toilier à Darnetal," 13 May 1783 AN F/12/994; "Dossier de rose de Smyrne de Osmont," 1783 AN F/12/1334B; Pierre-Joseph Macquer, Rapport de roses solides sur le coton par le Sieur Renauld de Rouen, 30 October 1782, AN F/12/994. back

Note 11: Louis-Auguste Dambourney, Recueil de procédés et d'expériences sur les teintures solides que nos végétaux indigênes communiquent aux laines & aux lainages. . . (Paris, 1786). back